Typically, concrete box culverts are manufactured using precast techniques, but occasionally cast-insitu (cast in place) construction is required. Each method has its own set of features, advantages, disadvantages, and applications:

Precast Box Culverts:

Key Features:

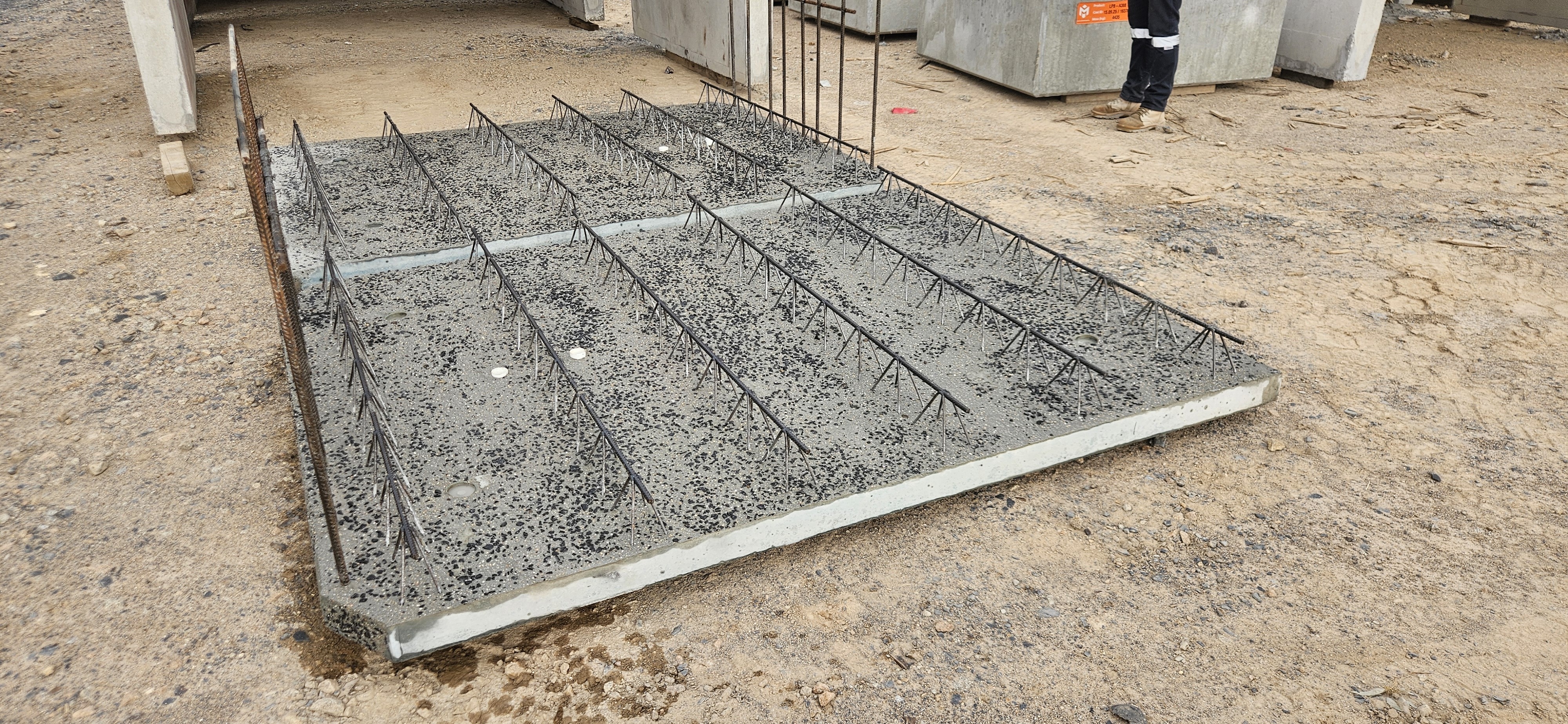

- Precast box culverts are manufactured off-site in a controlled environment and transported to the construction site in modular sections.

- They are manufactured from high-performing reinforced concrete and come in various standard sizes and shapes.

Advantages:

- Rapid Installation: Precast culverts can be installed quickly, reducing construction time and traffic disruptions.

- Quality Control: Manufacturing in a controlled environment ensures consistent quality and durability.

- Cost-Effective: In many cases, precast culverts can be more cost-effective than in-situ construction.

Disadvantages:

- Limited Customisation: Precast culverts are available in standard sizes and shapes. Some level of customisations is available, but this may not meet the exact specifications of every project.

- Transport Challenges: Transporting large precast sections to the site can be logistically challenging in some cases.

- Limited to Certain Sizes: Very large or non-standard culvert sizes may not be available as precast units.

Applications:

Precast box culverts are commonly used in road and highway construction, pedestrian underpasses, stormwater management, and utility channels.

In-situ (Cast-in-Place) Box Culverts:

Key Features:

- In-situ box culverts are constructed on-site, with concrete poured and formed directly in place.

- They can be customized to fit specific project requirements in terms of size and shape.

Advantages:

Customisation: In-situ culverts can be designed and constructed to meet unique project needs, including non-standard sizes and shapes.- Site Adaptability: They are suitable for projects with challenging site conditions or where precast units cannot be transported easily.

- Longevity: Well-constructed in-situ culverts can have a long service life.

Disadvantages:

- Longer Construction Time: Building in-situ box culverts takes longer than installing precast units.

- Higher Labour Costs: The labour required for construction on-site can be more expensive.

- Quality Control Challenges: Quality control can be more challenging compared to precast units.

- Concrete Availability: suitable concrete may not be available in remote areas.

Applications:

In-situ box culverts are commonly used in situations where a large amount of customisation is required, such as culverts for specific hydraulic or geometric requirements, or in areas with restricted access.

The choice between precast and in-situ box culverts depends on factors such as project specifications, site conditions, budget constraints, and construction timelines. In some cases, a combination of both methods may be used to optimize construction efficiency and cost-effectiveness. Consulting with civil engineers, precast manufacturers and civil contractors, and considering the specific project requirements will help in selecting the most appropriate culvert construction method.