Concrete curing is an essential process that governs the controlled hydration of freshly placed concrete. As the material transitions from plastic to hardened state, moisture naturally migrates from the surface. Should this moisture loss occur too rapidly, there is a heightened risk of surface cracking and a reduction in the ultimate strength and serviceability of the concrete.

Implementing a well-managed curing regime delivers several key benefits for infrastructure projects:

- Enhanced Durability and Design Life: Effective curing minimises surface cracking and limits permeability, safeguarding the reinforcement from moisture ingress and harmful contaminants.

- Improved Surface Hardness: Cured concrete exhibits higher abrasion resistance, particularly valuable in high-traffic and load-bearing environments.

- Increased Structural Strength: Adequate curing ensures the concrete achieves its intended design strength, meeting performance and functional requirements.

Due to its critical importance, the curing process is comprehensively addressed in Australian Standards and detailed within asset owner specifications, underscoring its role in delivering compliant, resilient infrastructure.

Curing Methods

A range of concrete curing methods are available, each offering distinct benefits and varying levels of effectiveness depending on project requirements and environmental conditions. The fundamental objective of these methods is to retain or regulate the release of moisture from the surface of the concrete, ensuring optimal hydration and long-term performance. Below are several widely adopted techniques in modern concrete construction:

Curing Compounds

Curing compounds serve as a practical method for controlling moisture loss in freshly placed concrete. These compounds are typically applied in liquid form to the concrete surface immediately after the initial set. Once dried, the compound forms a thin, semi-permeable membrane that significantly reduces the rate of evaporation, helping to preserve the moisture necessary for optimal hydration and strength development.

Application of curing compounds can be undertaken using a sprayer or roller, ensuring uniform coverage across all exposed surfaces. It is important to note that, for certain subsequent trades such as line marking or painting, the curing compound may need to be removed to ensure proper adhesion and finish quality.

Moisture Curing

Moisture curing is a traditional technique that requires maintaining a consistently wet surface on the concrete during the early stages of strength development. This method can be implemented by bunding and flooding horizontal surfaces, or by applying hessian or dedicated curing blankets that keep the concrete moist. For optimal results, the moisture curing process should be sustained for up to seven days. Due to the practicalities of containment and water management, this approach is generally most suitable for flat, horizontal elements.

Formwork

Retaining formwork around complex concrete elements serves as an effective method for limiting evaporation and maintaining ideal moisture conditions during curing. By keeping formwork in place for up to seven days, the curing environment is stabilized, supporting improved strength gain and durability in the finished element. However, this technique may not be feasible for high-volume precast manufacturing or where prompt reuse of formwork is required, as extended formwork retention can impact production efficiency.

Internal Waterproofing

Internal waterproofing technologies are increasingly utilised in modern concrete construction to support the curing process and long-term durability. These products work by chemically waterproofing the concrete matrix and trapping free moisture within the element, ensuring sustained hydration even after the initial set. Internal waterproofing agents can be incorporated directly into the concrete mix during batching or applied to the surface post-set, functioning similarly to conventional curing compounds but with the added benefit of enhancing resistance to water ingress throughout the structure’s service life.

Steam Curing

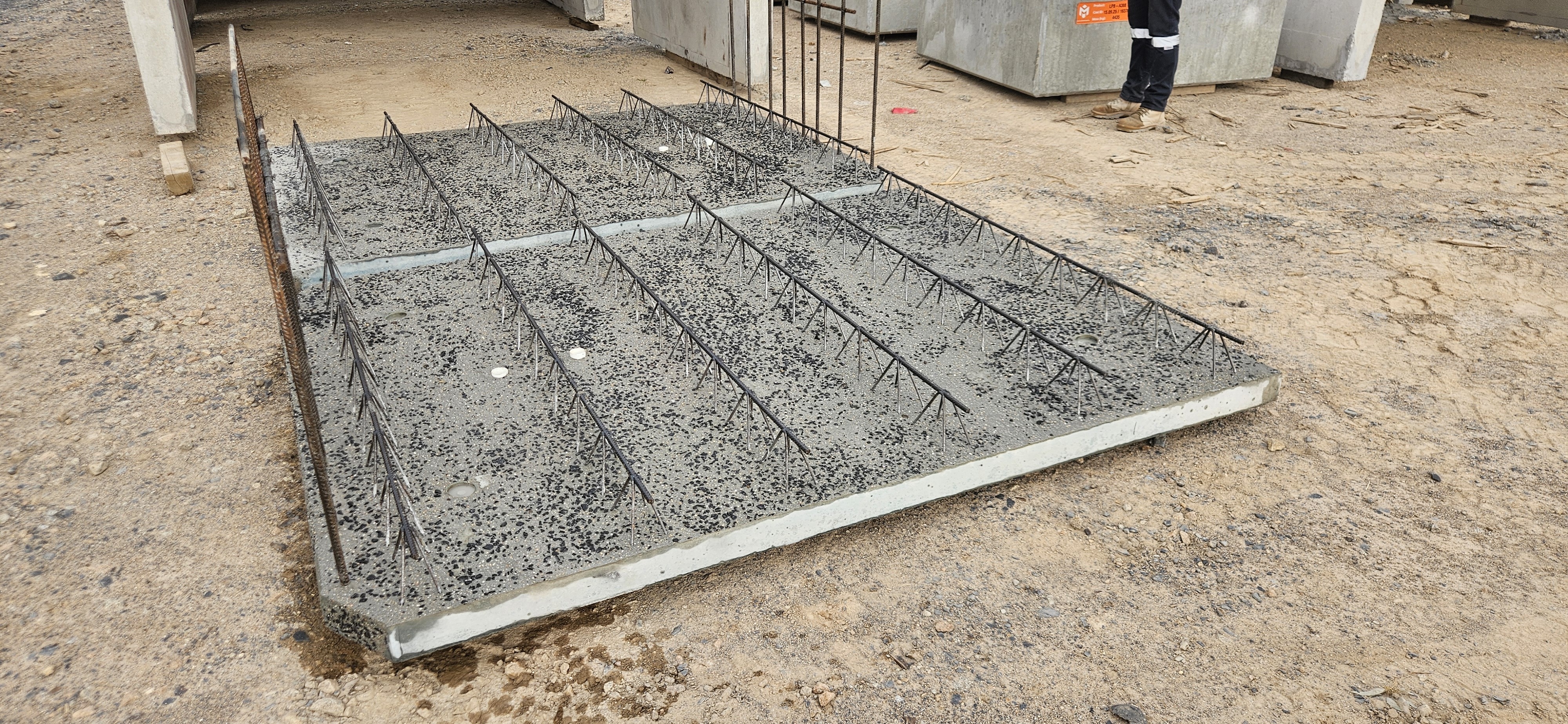

Steam curing is an advanced thermal curing technique widely adopted in precast manufacturing to accelerate concrete strength development and enhance overall durability. This method involves exposing concrete elements to controlled steam environments, where the combination of elevated temperature and moisture expedites the hydration process. The key benefits of steam curing include significantly faster strength gain—enabling earlier demoulding and handling—and a substantial reduction in overall curing time, with the process often completed in hours rather than days. Due to these advantages, steam curing is especially effective for precast civil infrastructure applications where rapid production schedules and consistent quality are paramount.

How is Steam Curing Undertaken?

To implement steam curing effectively, the freshly cast concrete element must first be fully encapsulated to retain both steam and heat throughout the process. This encapsulation can be achieved by placing moulds within sealed chambers or covering them with waterproof tarpaulins. Steam, generated by an industrial boiler, is then introduced to the curing environment via a network of piping to surround the concrete elements.

During this process, temperature sensors are strategically positioned within the moulds to monitor heat distribution and track peak temperature levels. Careful temperature control is essential; allowing the element to become too hot too quickly can inhibit or halt the critical chemical reactions—the hydration process—responsible for achieving target strength and durability in the concrete.

Curing Standards

Concrete curing standards provide comprehensive guidance on the approved methods, durations, and conditions required to achieve optimal material performance and compliance with regulatory expectations.

It is essential for precast manufacturers and concrete contractors to possess an in-depth understanding of these standards and to implement processes accordingly. A detailed description of the selected curing method—along with relevant monitoring and verification measures—should be documented within an Inspection and Test Plan (ITP). This documentation assures asset owners and head contractors that the curing process will be executed effectively, resulting in consistent quality and long-term durability of the constructed asset.

In Summary

Curing is a fundamental step in the production of both precast and in-situ structural concrete, directly influencing the material’s long-term durability, load-bearing capacity, and service life. The strict application of industry standards to all curing processes is essential to ensure the concrete achieves the specified mechanical properties and performance benchmarks, delivering reliable outcomes for critical infrastructure projects.

Need more information?

The expert team at Modcast can assist in assessing the curing requirements on your project and provide advice on potential impacts to design and cost.