Monolithic headwalls offer significant advantages for RCBC Culvert Projects, providing opportunities to reduce costs, save time, and enhance safety on construction sites.

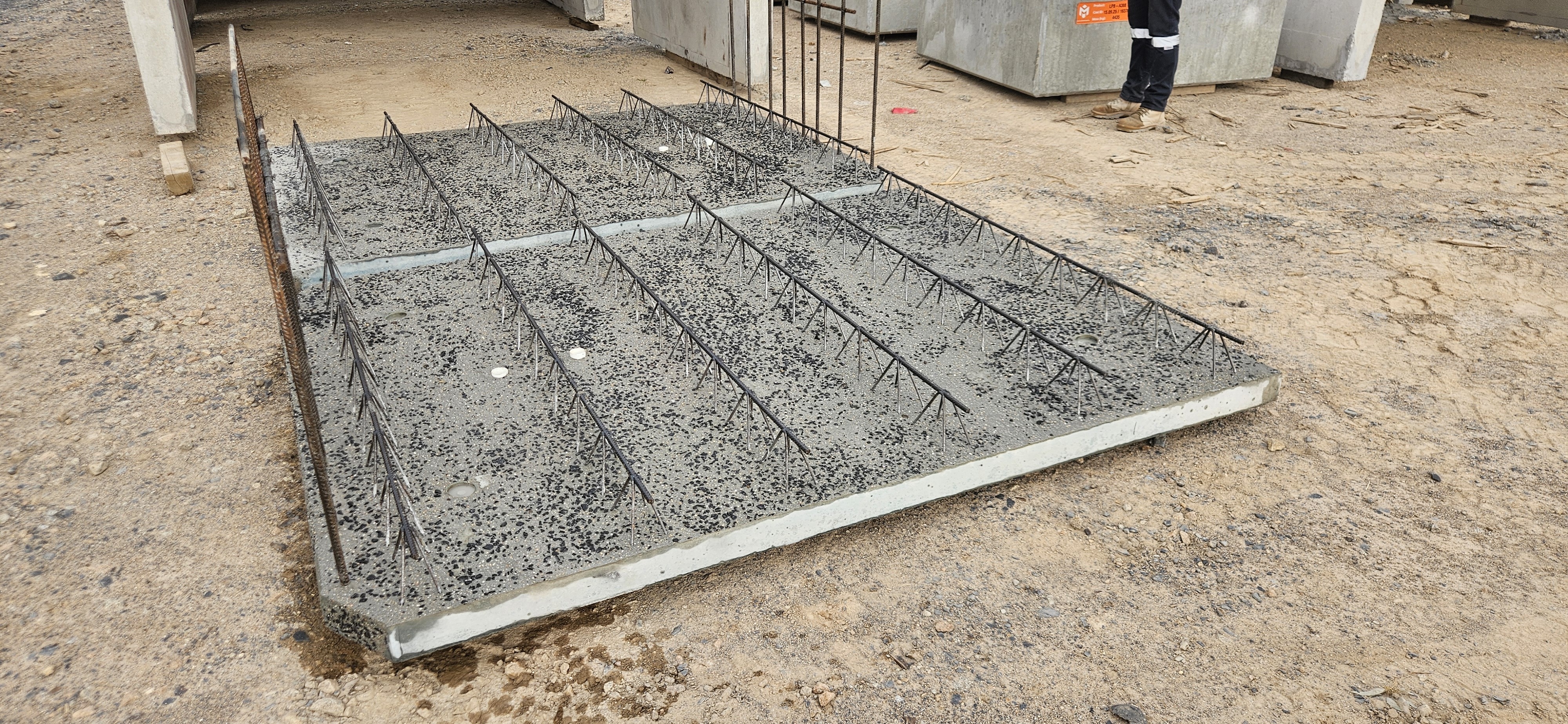

To begin, it is helpful to define what a monolithic headwall is. This technique involves the precast manufacturing of the headwall or kerb section as a single, continuous piece along with the exterior portions of the culverts in a large RCBC structure. In contrast, traditional approaches to large culverts and multicell structures typically require headwalls to be constructed and cast onsite, while smaller installations may integrate the headwall into a one-piece wing wall element.

Adopting a monolithic casting approach delivers several benefits, particularly for complex construction programs, including:

Cost

When evaluating project costs, it is important to account for the expenses associated with FRP trades, formwork, and the need for temporary site access when constructing headwalls onsite. By shifting this process to a controlled precast facility, these costs can be substantially minimized, resulting in more efficient budget allocation and streamlined project delivery.

Time

Constructing headwalls onsite—comprising steps such as formwork assembly, concrete pouring, and curing—can extend over the course of a week. During this period, essential follow-up activities like backfilling above the structure are placed on hold, potentially impacting the project schedule. By employing monolithic headwalls, teams can resume construction and commence backfilling almost immediately after installing the culvert units. This expedited process proves especially beneficial for projects with stringent timelines, such as rail occupations, where every hour of progress is critical.

Aesthetics

Traditional cast-in-place headwalls often produce visible construction joints, inconsistencies in color, and an increased risk of water leakage. In contrast, monolithic headwalls are manufactured as a seamless, single-piece unit, resulting in a more uniform appearance and enhanced visual appeal for the completed structure. This integrated approach contributes to improved overall aesthetics and long-term durability.

Safety

Monolithic headwalls significantly improve onsite safety, particularly when working with elevated culverts. By eliminating the requirement for trades to operate along the outer edges of the structure, the need for access platforms is reduced, subsequently lowering the risks associated with working at height. Moreover, temporary or permanent handrails can be pre-installed on the kerbs before placement, delivering essential edge protection throughout backfill operations and further supporting a safer work environment.

Other Factors

To support a deeper understanding of monolithic headwalls and their applications, it is important to consider some frequently asked questions:

What Size Culvert Can Use Monolithic Headwalls?

Monolithic headwalls are adaptable and can be precast for a wide range of culvert sizes, from compact 300 x 300 millimetre units to expansive rail underpass structures. The benefits of monolithic headwalls are especially pronounced for larger culverts and multicell configurations, where smaller one-piece wing wall solutions may not provide adequate structural or operational advantages.

How High Can Monolithic Headwalls Be?

Monolithic headwalls are typically designed up to a height of 700 millimetres. For headwalls exceeding this height, structural considerations may require the use of L-shaped wall elements to provide additional stability and to prevent overturning of the exterior culvert sections. This ensures both the safety and longevity of the installation in demanding conditions.

Can Other Items be Cast In?

Yes, in the controlled precast environment, accessories such as ferrules and drainage tubes can be accurately cast into the headwall, further saving time on site.

Need more information?

The expert team at Modcast can assist in assessing the suitability of monolithic headwalls on your project and provide advice on potential impacts to design and cost.