Customising your precast concrete box culvert design can enhance its functionality, durability, and aesthetics. Here are several customisation options to consider:

- Size and Shape: Customise the dimensions and shape of the culvert to fit the specific site requirements. This includes adjusting the width, height, and length to accommodate different flow rates, traffic loads and site conditions.

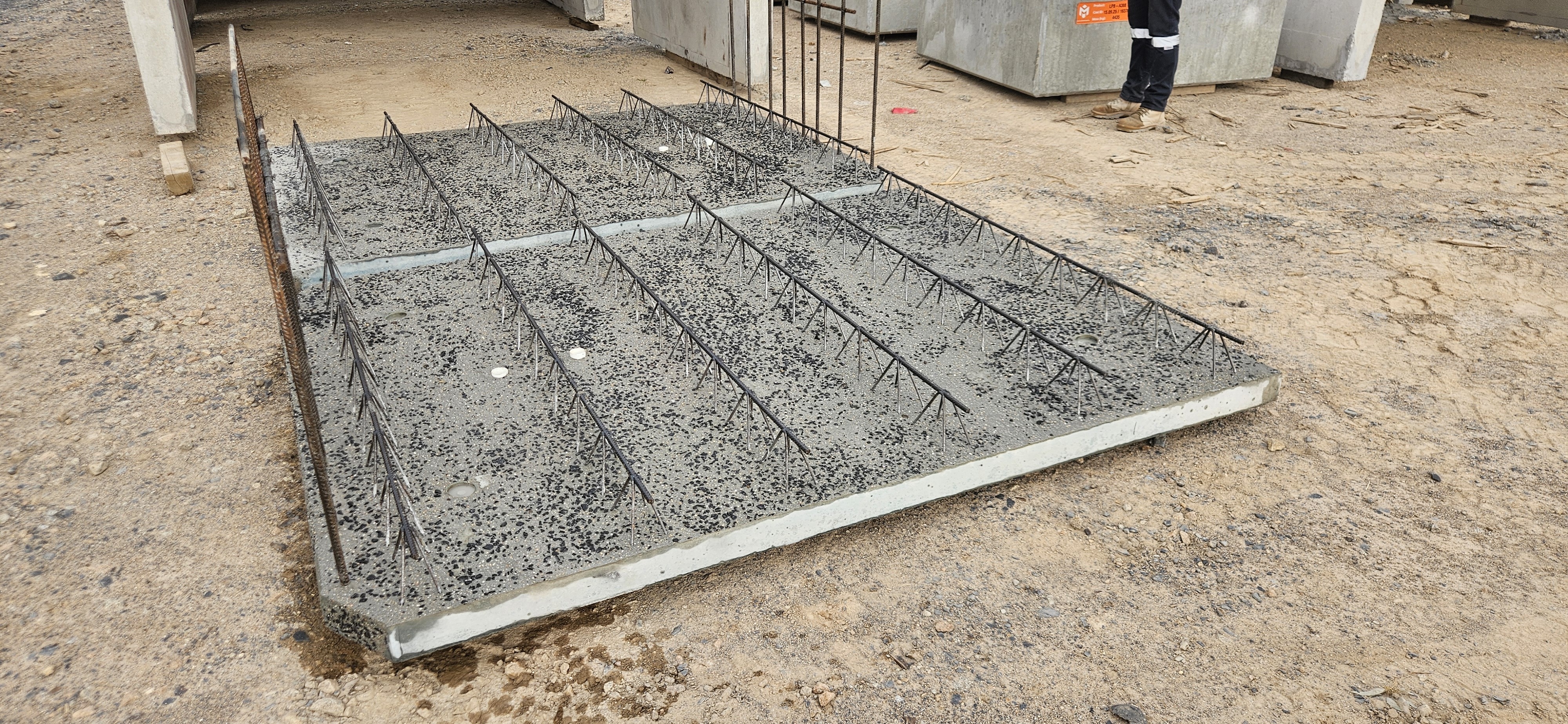

- Materials: Choose the type of concrete mix and reinforcement materials that best suit the project's needs. Specialised mixes may be specified to suit the requirements of a particular product application, road authority standard, or environmental requirement. Fiber-reinforced concrete may be suitable for some applications.

- Load Capacity: Designs can be altered to increase the load-carrying capacity to support heavier loads, such as for heavy traffic or industrial applications, or optimised for lighter loads in alternative applications.

- Inlet and Outlet Design: Customize the inlet and outlet configurations to match the hydraulic conditions of the site. This may include wing walls, aprons and headwalls, which can all be designed to suit the site conditions.

- Waterproofing: Apply waterproof coatings or additives to the concrete to enhance its resistance to water penetration and corrosion. This may be important in areas with high groundwater levels or exposure to harsh environmental conditions.

- Corrosion Protection: Consider adding corrosion-resistant coatings or reinforcing materials, such as galvanised or epoxy-coated rebar, to prolong the culvert's lifespan, especially in aggressive chemical or marine environments.

- Aesthetics: Incorporate architectural features or decorative elements to make the culvert visually appealing. This can include textured finishes, coloured concrete, or even artwork if the culvert is in a public space.

- Joint Sealants: Specialized joint sealants may be specified in some situations to prevent water infiltration and soil erosion at the joints between culvert sections. Proper sealing is crucial for maintaining structural integrity.

- Environmental Considerations: Customize the culvert design to meet environmental regulations and considerations. This may involve incorporating wildlife-friendly features like fish baffles or wildlife shelves.

- Access and Maintenance: Design the culvert with access points and maintenance features in mind, such as inspection chambers, manholes, or access hatches for cleaning and inspection.

- Specialized Features: If your culvert serves a unique purpose, consider specialised features like sluice gates, flow control devices, or monitoring

- Safety Measures: Integrate safety features such as guardrails, reflective markers, or anti-skid surfaces if the culvert is located in areas with high traffic or pedestrian use.

Customizing your precast concrete box culvert design should involve collaboration with engineers, architects, precast manufacturers, and other relevant experts to ensure that the design meets all functional, regulatory, and aesthetic requirements for your specific project.