What is ECI?

Early Contractor Involvement, or ECI, is a strategic construction procurement method that involves engaging contractors during the design phase. This approach differs from traditional procurement methods where contractors and suppliers are typically brought in after the design is already completed.

ECI allows for the valuable expertise of contractors and stakeholders to be utilized during the design phase, leading to enhanced project outcomes.

Benefits of ECI for Precast Concrete

There are numerous advantages to be gained from involving a precast manufacturer in the design of a complex infrastructure project. These include:

- Addressing Project Challenges: Complex infrastructure projects often come with specific design or construction challenges such as installation methods, access constraints, and tight programming schedules. Early engagement with manufacturers can leverage their expertise to find solutions to these challenges.

- Cost Certainty: Precast manufacturers can offer accurate cost guidance for complex elements, leading to improved feasibility study estimates and project budgets, ultimately minimizing cost overruns.

- Cost Savings: Leveraging their manufacturing knowledge, precast manufacturers can identify opportunities to simplify designs or suggest alternative cost-effective options.

- Manufacturability: The ideal design of a precast element in an engineer's eyes may not always be feasible or cost-effective to manufacture. Manufacturers can review designs to ensure they align with standard manufacturing methods and capacities.

- Innovation: Early involvement with manufacturers opens up opportunities to implement innovative solutions, including sustainability enhancements, improved ease of installation, and transportation efficiencies based on past project experience.

- Lead Times: Stakeholders often underestimate the lead times required for designing and manufacturing custom precast elements. Early engagement helps in understanding accurate lead time estimates, aiding in project planning to avoid costly delays and set realistic expectations.

- Streamlined Procurement: Confirming design, lead times, and contract terms early on allows for a more efficient procurement process with reduced resource requirements.

- Reduced Risk: An open and transparent ECI process helps in identifying and mitigating risks early on, reducing uncertainties.

- Reduced Variations: While some benefits can be achieved through traditional procurement processes, introducing innovations and design changes after the initial design phase can lead to costly delays as changes need approval and negotiations over cost variations.

Strategic Partnership

Forming a strategic partnership with a precast manufacturer ensures the efficient allocation of resources and guarantees a steady supply once the project transitions into the construction phase.

Types of ECI in Precast

Early involvement of a precast manufacturer offers various pathways depending on the project structure:

Design Collaboration / Specification – Precast manufacturers provide valuable insights to designing engineers on manufacturability, sustainability options, and cost-saving opportunities. This collaboration allows designers to integrate the product seamlessly into their designs, providing clarity during the procurement phases.

Project Management Collaboration – Accurate cost and lead time estimates, along with efficient resource allocation, can reduce lead times and minimize program risks.

Design & Construction Integration – In addition to enhancing design and project management aspects, innovative approaches can be implemented to optimize installation methodologies.

ECI Best Practice

Here are some key strategies to maximize the benefits of the ECI concept:

- Early Engagement: The sooner you involve a contractor, the more advantages you'll gain from the partnership. Understanding costs and constraints early on can save significant time in the design phase. For instance, a designer can avoid wasting time on a precast option that may not be feasible to manufacture.

- Establish Clear Objectives: It's essential to start the partnership with well-defined objectives and expectations from all stakeholders. This will help prevent disagreements, misunderstandings, and delays later in the procurement process. For example, clarifying the level of exclusivity the contractor has at each stage can impact the resources and costs involved.

- Maintain Clear, Consistent, and Regular Communication: Effective and transparent communication throughout the ECI phase is crucial for keeping expectations aligned and updated during the design and procurement stages.

ECI Case Study

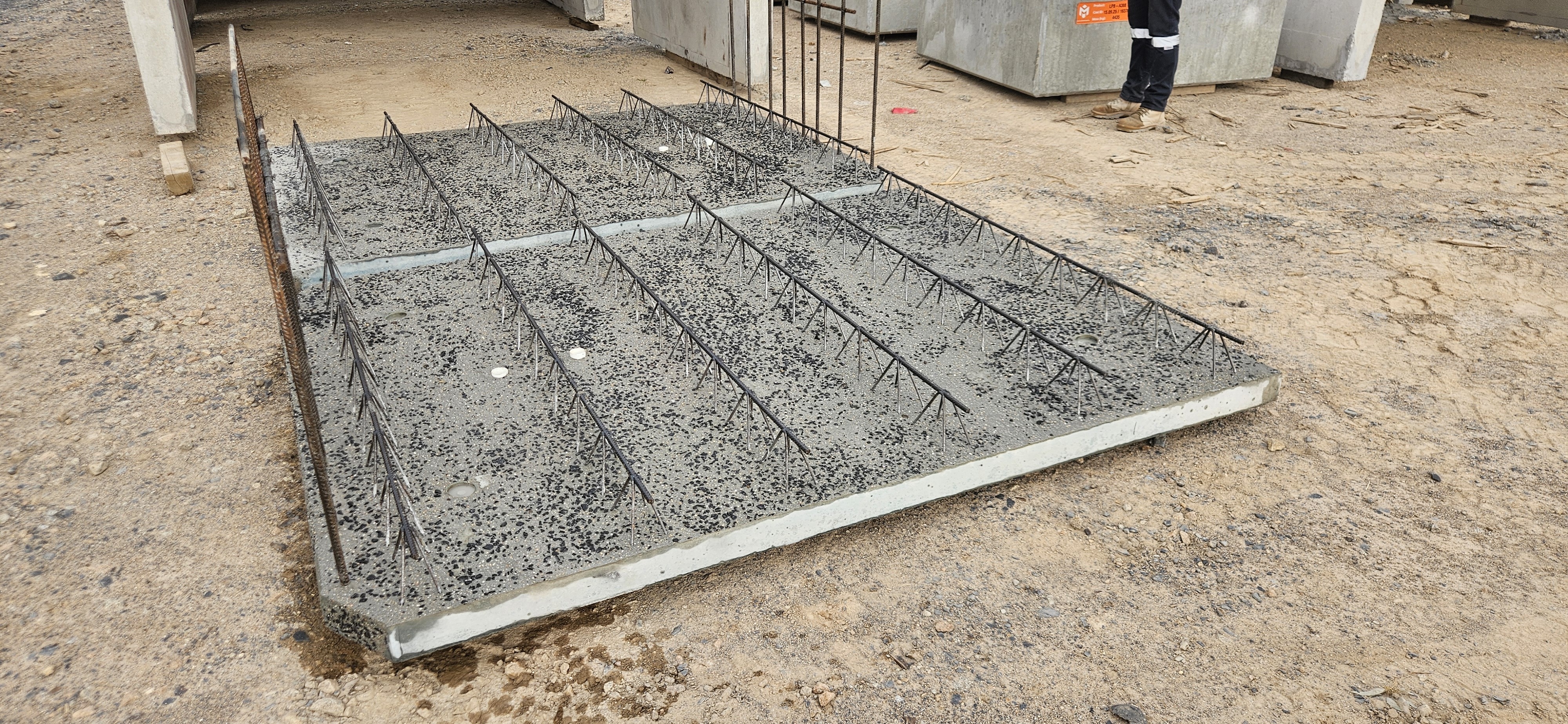

A top-tier contractor was tasked with designing and constructing several major culvert replacements in the Northern Suburbs of Melbourne as part of the Major Road Projects Victoria (MRPV) panel. The structures were crucial for providing access to residential areas and schools, posing a challenge to complete the installations during the school holiday period. Traditionally, major culverts are built on a 'cast-in-place' base slab, but this method would not be feasible within the restricted 2-week holiday timeframe.

Facing this challenge, the contractor collaborated with Modcast early in the design phase, working closely with both the contractor and designers to develop, cost, and program a precast base concept. By opting for precast bases instead of cast-in-place bases, the installation time was significantly reduced. This innovative approach was presented to MRPV, who approved it based on the promising project outcomes.

Following a streamlined procurement process, Modcast successfully delivered a complete RCBC Culvert package, including the innovative precast base system. The contractor managed to install the structures in just a few days, ensuring the road was back in full service within the required time frames.

In contrast, if the contractor had not engaged with Modcast until the traditional post-award procurement phase, designing and delivering a precast base solution within the necessary time frame would have been unattainable.

Is ECI a fit for my project?

If more than a few of the following questions ring true for your project, early engagement of a precast manufacturer could greatly benefit your project outcomes:

- 1. Complex custom precast elements will be required.

- 2. Uncertain stakeholder approval requires accurate costings and lead times for a feasibility study.

- 3. Program pressure and time sensitivity through design and construction.

- 4. Construction challenges that will require innovative solutions to overcome.

Could ECI benefit your next project? Reach out to Modcast for an obligation free discovery call to discuss.